The Overlooked Essential: Why A Good Saddle Matters

By Syed in Uncategorized Posted January 18, 2025

The most important piece of your S-style electric guitar is one you rarely see and may have even forgotten exists. No, I don’t mean the lucky pick in your wallet.

I’m talking about the saddle. Not the kind you put on a horse, though the metaphor fits. I’m talking about guitar saddles – the humble, hardworking hardware that sits patiently on the bridge. You may not know it, but that little piece of metal is one of the things that makes your guitar an instrument.

If you’re a luthier, a sound engineer, a musician, or an artisanal guitar builder, the saddle is more important to your craft than you might think. It is the point of contact between the string’s vibration and the body of the guitar, allowing the guitar to resonate.

A luthier can build the best guitar with the highest quality tonewoods. A sound engineer can have the finest instruments and equipment in their recording studio. A guitarist can play like the next David Gilmour. But if their guitars have bad saddles, they will never reach their full potential.

Neglecting the saddle is like buying a racehorse and riding it with a cushion beneath you. The horse will still run, but you won’t be winning any races, and you’ll be in for a world of pain. A good horse needs a good saddle. So does a guitar.

What Does a Saddle Actually Do?

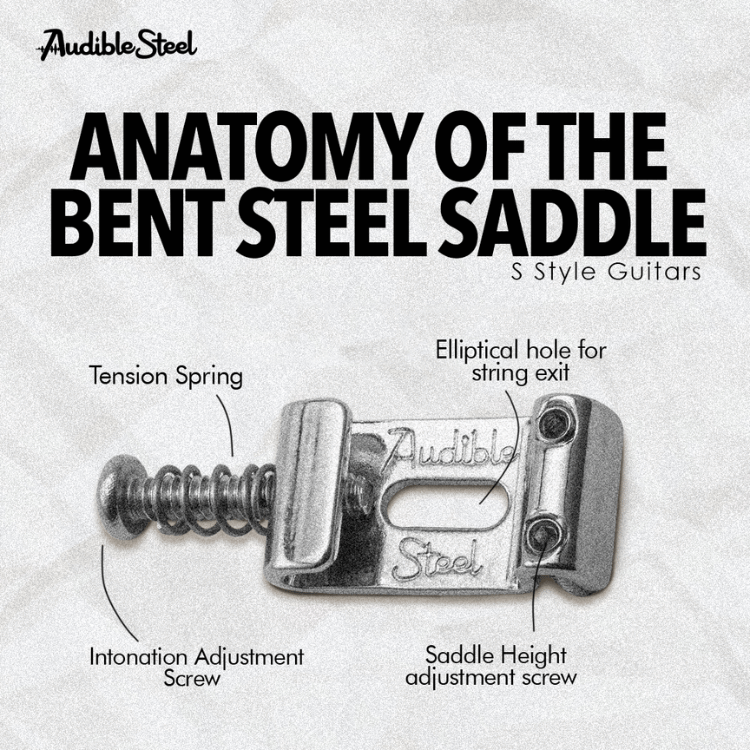

A guitar saddle isn’t just a string holder. Just like on a horse, the saddle is the intermediary between the artist and their instrument: it takes the vibration from the strings and transmits it to the wood. As such, the saddle does much of the heavy lifting of producing the instrument’s sound. The better it does this job, the more your guitar sings.

Additionally, by holding the strings in place, a good saddle helps a guitar stay in tune and relieves friction on the strings, reducing the chance of them breaking. A good saddle can make a $100 starter guitar sound top-shelf, and a boutique masterpiece sound truly out of this world.

But a bad saddle chokes the tone and leaves the wood whispering instead of roaring. A bad saddle compromises the fineness of the luthier’s build, the resonance of the sound engineer’s recordings, and the integrity of the player’s tune.

And the crummy thing about today’s guitars? A lot of them have bad saddles.

Why Most Saddles Suck

Let’s be blunt: modern saddles often aren’t great. Cost-cutting, outsourced production, and a lack of attention to detail have turned one of the original inventor’s most thought-out parts into an afterthought. How do I know? Because I’ve seen how it used to be done, and the difference is night and day.

A guitar player for over 40 years, I have spent years living, playing, and tinkering with vintage guitars – real beauties from the ’50s and ‘60s. I used to wonder why they sounded so much better than the newer ones. Cleaner separation of notes. Bolder, more resonant.

It felt like magic until I got under the hood and realized the difference: it was the intention and care that was put into every part of the original design – even the saddles. Especially the saddles.

That was when I found my calling. I knew I had to revisit history, and build saddles like they used to, with the respect they deserve. And so, I founded Audible Steel.

The Audible Steel Difference – Proof You Can Hear, Feel, and Even See

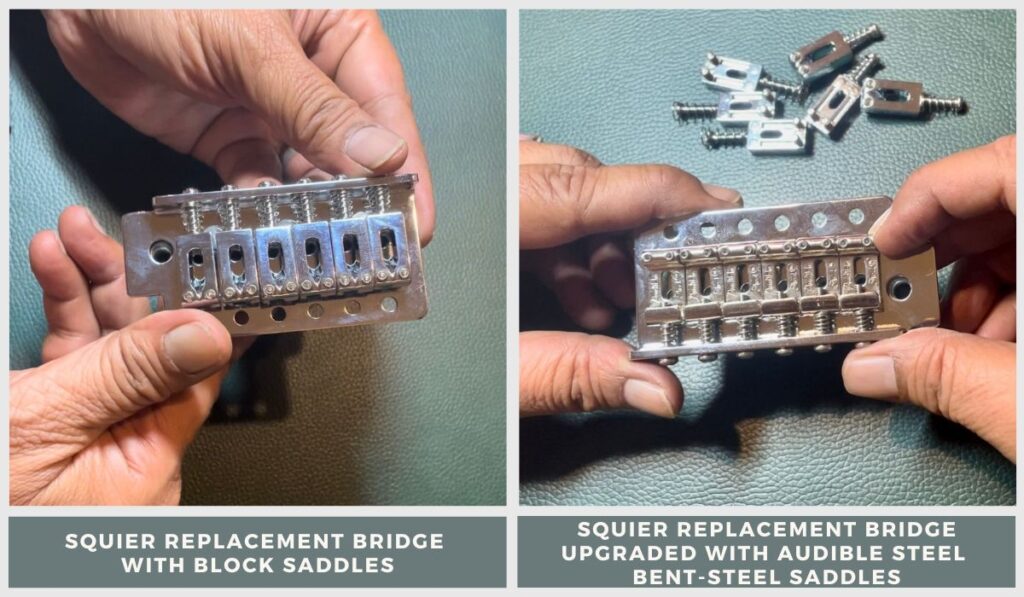

Audible Steel saddles are built with the same passion and precision as the vintage masterpieces I fell in love with back then. They combine the meticulous craftsmanship of the original S-style builds with the insights of a seasoned musician who wants a more in-tune and better playing experience.

Designed and built with the ideal materials and dimensions and thoroughly tested, our saddles are for the pros who care about every detail – and the weekend warriors who just want their guitar to sound play better.

Here’s what sets them apart:

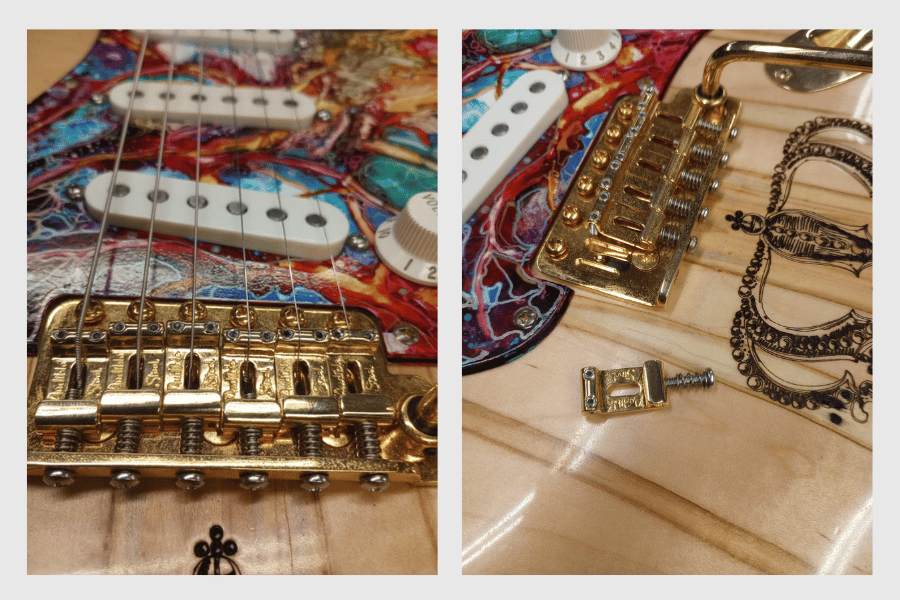

- For Luthiers and Boutique Builders: You take pains to source the best materials for your builds, and they deserve the best resonance and quality possible. These saddles let the wood do its job, amplifying its natural tone beautifully.

- For Sound Engineers: Richer, fuller, cleaner tones and a naturally higher decibel output optimize your recordings. Indeed, we encourage you test Audible Steel saddles on any software that provides a graphic representation of sound frequencies – you will see that our saddles give higher decibel output and better resonance. You want the best sound possible in your recordings, so you invest in quality instruments. Let them have quality saddles.

- For Musicians: A big, bold sound, less string breakage and better tuning stability means fewer headaches. Your guitar will stay in tune even after the most aggressive playing. Kurt Cobain would deliberately perform a half-step down just to keep his guitar tuned a little bit longer. But with Audible Steel saddles, the Grammy-nominated Eric Gales says he can “play long and hard and they don’t give me any trouble.” Eric likes our saddles so much, he uses them for all his custom builds now.

You Deserve the Best

If you’re in the business of building, recording, or playing guitars, perhaps it’s time to stop overlooking the saddle. This little piece of hardware can make or break your build quality, your recordings, and your playing experience.

Audible Steel saddles are for folks who demand the best, whether you’re crafting a boutique beauty or just trying to keep your gig guitar in tune through a set.

So what are you waiting for? Give your guitar the respect it deserves with Audible Steel saddles.

– Jay

Founder, Audible Steel